CALL 800-985-6929

Mon-Fri 7AM - 7PM CST

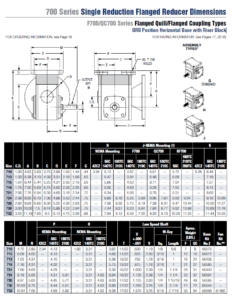

Boston Gear 700 Series Single Reduction Worm Gear

Our standard 700 Series – the heart of Boston Gear’s speed reducer product line – has been serving industry reliably for over 40 years. Its proven modular design has set the industry standard for performance and is the most imitated product in today’s worm gear speed reducer market. But why settle for a knock-off when you can have the original – from Boston Gear.

CATALOG & MANUALS

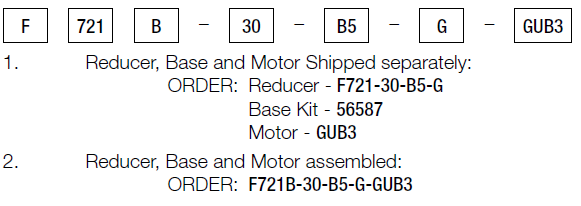

Single Reduction Numbering System / How to Order

When ordering reducers please include code letters for Style, Size, Base (if required), Ratio, Fan (if required), Lubrication (if required),

NEMA Mounting (if flanged reducer), Shaft Assembly and Motor (if required).

EXAMPLE:

Required size, 721 Quill types flanged reducer, 30:1 ratio, 5/8” input bore, standard assembly, with horizontal base, no lubrication.

Motor to be 3/4 HP, 1750 RPM, 230/460 Volt, 3 Phase, 60 cycle, open dripproof.

Style – Designates reducer or flanged reducer, projecting or hollow output shaft.

| C | Designates cast iron flange and base. (Standard on motor flanges 3 HP (180TC) and up and all bases except horizontal (710-726). |

| Blank | Single reduction reducer with projecting input and output shafts. (No code letter required). |

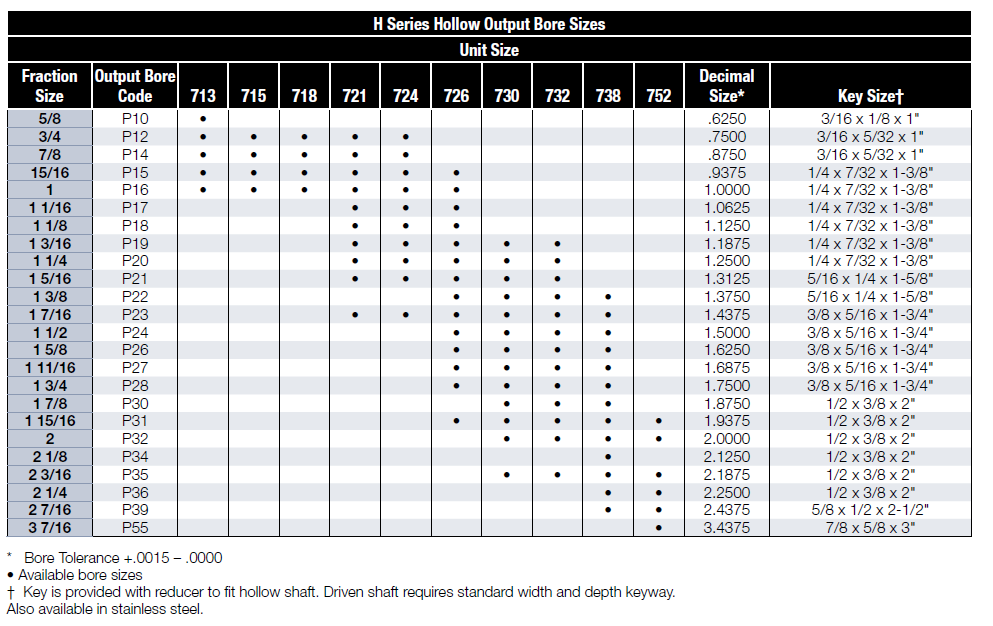

| H | Single reduction reducer with projecting input and BostMount hollow output shaft. (No flange) ( 713-738) |

| S | Single reduction reducer with hollow output shaft. (Sizes 718, 721, 726 and 732). |

| F | Single reduction flanged reducer (Quill types) with projecting output shaft. |

| HF | Single reduction flanged reducer (Quill types) with BostMount hollow output shaft. (Sizes 713-738) |

| QC | Single reduction flanged reducer (Coupling types) with projecting output shaft. |

| HQC | Single reduction flanged reducer (Coupling types) with BostMount hollow output shaft. (Sizes 713-738) |

| RF | Single reduction flanged reducer (Coupling types) with Projecting output shaft. 752 – 760 Size Only |

| BK | Designates Cast Iron, White BostKleen paint |

| SBK | Designates Cast Iron, Stainless BostKleen paint |

| SSF | Stainless Steel Single reduction flanged reducer (Quill types) with projecting output shaft. |

| SSHF | Stainless steel single reduction flanged reducer with BostMount hollow output shaft. |

SIZE – Center distance, rounded off.

710 – 1.00

713 – 1.33

715 – 1.54

718 – 1.75

721 – 2.06

724 – 2.38

726 – 2.62

730 – 3.00

732 – 3.25

738 – 3.75

752 – 5.16

760 – 6.00

BASE – Base positions relative to output shaft. Shipped separately as Base Kits.

| Blank | No base kit supplied |

| A,B | Horizontal bases |

| C,D,E & F | Vertical Bases0 |

| R/L | BostMount Output Bracket |

| X | Input Vertical Up |

| Y | Input Vertical Down |

| BRB | Horizontal base with riser block |

| V,W | Flanged bases, available on “S” hollow shaft models only. Factory assembled. |

| M/N | Flanged bases, available on “CFA” hollow shaft models only. |

Lubrication Optional Prelubrication.

Blank – No Lubrication supplied.

K – Klubersynth UH1 6-460

S – Mobil SHC634 Synthetic Lubricant

X – Mobil 600W

*When specifying optional prelubrication, include

mounting position after shaft assembly.

Optional fan available on sizes 732-760 single reduction only. Shipped separately as Fan Kit. See Page 130.

Blank – No Fan Kit.

E – End Cap (standard)

F – Fan Kit

VENT – Pressure Relief.

Blank – Standard Vent

P – 5 PSI Vent

Z – PosiVent® Pressure Compensationg Bladder

Oil Seals

Blank – Standard Seal

T – Double Input Seals. Recommended for mounting positions 2, 3, 4, 6

C – High pressure/wash down configuration for stainless gearboxes. Contains double input seals and axial face seals on the output.

Shaft Assembly Assembly shaft arrangements.

G – Standard assembly (left)

H – Double output shaft projection

J – Opposite to standard (right)

GS – Stainless standard assembly (left)

HS – Stainless double output shaft projection

JS – Stainless opposite to standard (right)

Single Reduction Speed Reducer Selection Procedure

Single Reduction Speed Reducer Selection Procedure

To properly select a speed reducer, the following application information must be known:

Input RPM (Ratio)

Output Torque

Input Horsepower

Service Factor

Non-Motorized Speed Reducer

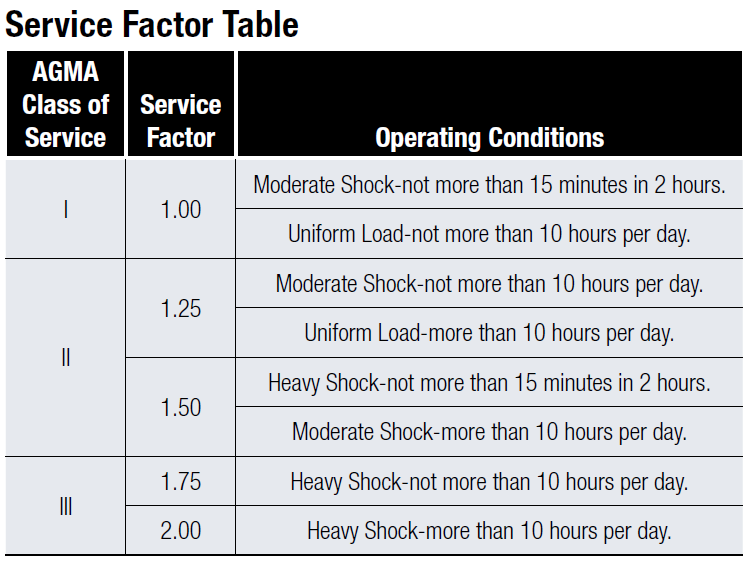

1. Determine service factor from table below.

2. Determine design horsepower.

Design Horsepower = Application Load x Service Factor

3. Select a speed reducer size that satisfies output RPM, service class and/or output torque requirements.

4. Check overhung load capacity.

Motorized Speed Reducer

1. Determine service class from table below.

2. Select a reducer size that satisfies output RPM, service class and/or output torque requirements.

3. Check overhung load capacity.

Overhung Load

If the output shaft of a speed reducer is connected to the driven machine by other than a flexible coupling, an overhung load is imposed on the shaft. This load may be calculated as follows:

OHL = 2TK

D

OHL = Overhung Load (LB.)

T = Shaft Torque (LB.IN.)

D = PD of Sprocket, Pinion or Pulley (IN.)

K = Load Connection Factor

Load Connection Factor

Sprocket or Timing Belt . 1.00

Pinion and Gear Drive . 1.25

Pulley and V-Belt Drive 1.50

Pulley and Flat Belt Drive 2.50

An overhung load greater than permissible load value may be reduced to an acceptable value by the use of a sprocket, pinion or pulley of a larger PD. Relocation of the load closer to the center of reducer will also increase OHL capacity.

Permissible Overhung Loads and Output Shaft Thrust Loads are listed for each reducer in the Tables on pages 30-33.

Maximum Input Speeds

710, 713 4500 RPM

715 through 732 3600 RPM

738, 752 2500 RPM

760 1750 RPM